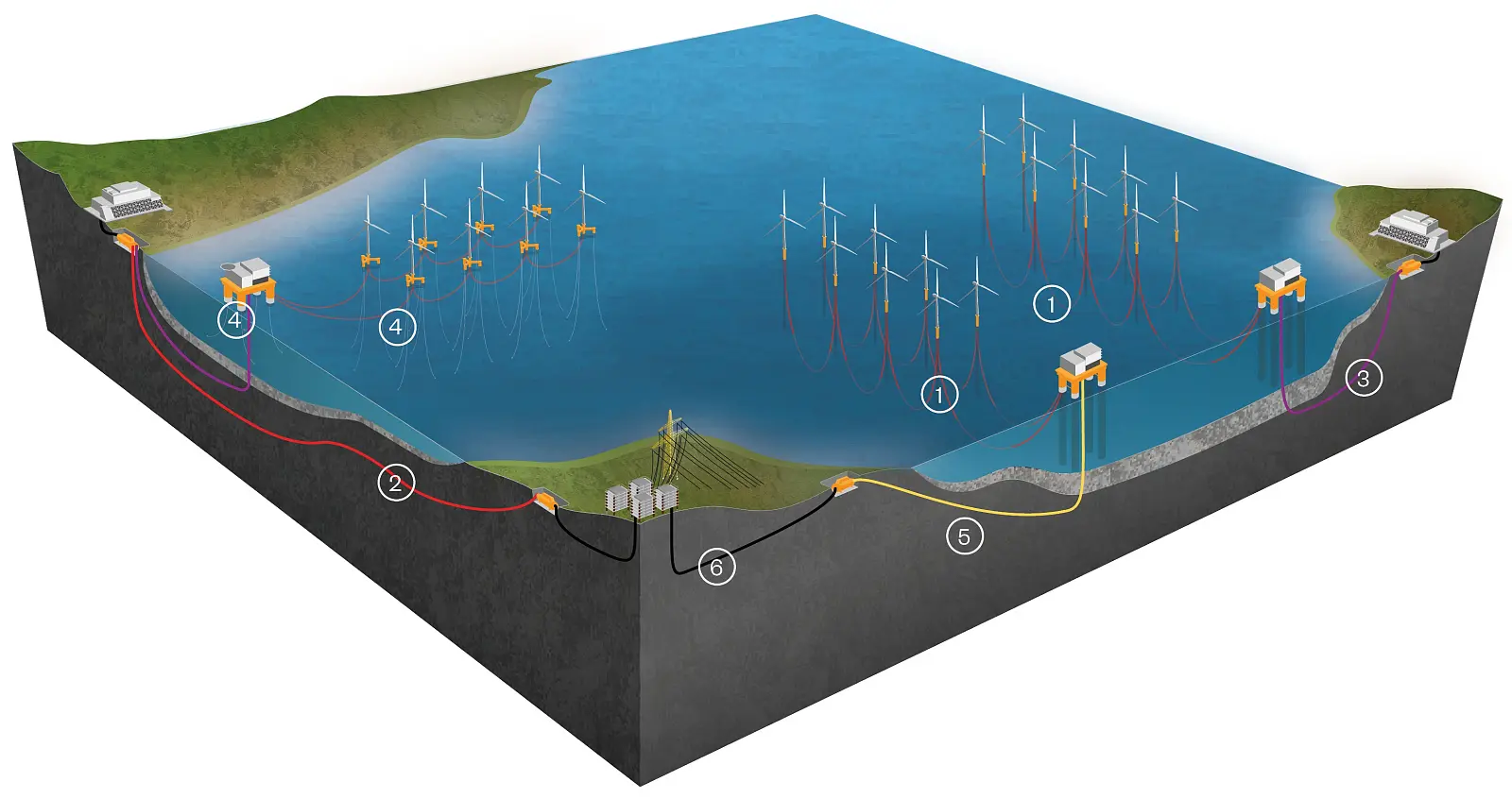

JDR Cable Systems, in collaboration with TFKable, plays an integral role in the global energy transition, supplying subsea cables for major offshore wind projects. Over the past 15 years, JDR has delivered over 4,000 km of subsea cables, enabling global offshore wind power transmission. As an early innovator in 66 kV inter-array cables, JDR has helped integrate larger turbines, enhancing efficiency and reducing costs. Additionally, JDR pioneered dynamic power cables for floating offshore wind farms, solidifying its leadership in next-generation offshore energy solutions.

In 2024, JDR completed the type test qualification for its 132 kV static array cable, designed for next-generation offshore wind turbines. Developed with support from the Offshore Wind Growth Partnership and in collaboration with leading material suppliers, this technology was tested at the Offshore Renewable Energy Catapult. It will be produced at JDR’s upgraded Hartlepool facility and its new high-voltage manufacturing plant in Cambois, near Blyth, Northumberland. The 132 kV technology, which doubles the voltage of the 66 kV industry standard, improves energy transmission, reduces costs, and lowers clean energy prices for consumers.

![numeryok.jpg [5.47 KB]](https://www.jdrcables.com/storage/image/core_files/2025/2/21/4fa0d7d7667f63ef4dd7266969c4a6ae/jpg/tfkable/preview/numeryok.jpg)

![numeryok3.jpg [5.80 KB]](https://www.jdrcables.com/storage/image/core_files/2025/2/21/43876e1f1f410f66e0fb2423fc20b99f/jpg/tfkable/preview/numeryok3.jpg)

![numeryok5.jpg [5.74 KB]](https://www.jdrcables.com/storage/image/core_files/2025/2/21/2f753715b604c6a29f78ac1d7ec6fb86/jpg/tfkable/preview/numeryok5.jpg)

![numeryok2.jpg [5.68 KB]](https://www.jdrcables.com/storage/image/core_files/2025/2/21/84200a7883d9e1f7be8e2119a704459b/jpg/tfkable/preview/numeryok2.jpg)

![numeryok4.jpg [5.68 KB]](https://www.jdrcables.com/storage/image/core_files/2025/2/21/d98a1f09dd0e58639315e40705d4c64e/jpg/tfkable/preview/numeryok4.jpg)

![numeryok6.jpg [5.83 KB]](https://www.jdrcables.com/storage/image/core_files/2025/2/21/beb8b01eb7ba2c927ab6e077dbb61eea/jpg/tfkable/preview/numeryok6.jpg)