JDR adopts new resonant test technology from HIGHVOLT for 66 kV offshore windfarms

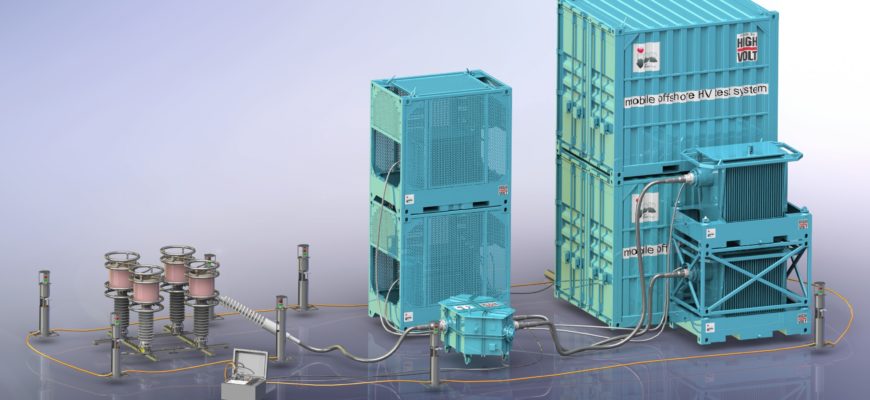

: HIGHVOLT Prüftechnik Dresden GmbH and JDR Cable Systems, part of the TFKable Group, are pleased to announce the adoption by JDR of a state-of-the-art Resonant Test System (RTS) to support its offshore windfarm commissioning projects. The test system is designed and manufactured in Dresden, Germany, by HIGHVOLT. It is purpose built for post installation testing of 66 kV offshore inter array cables (IAC) according to the international standard IEC 63026.

RTS is well established in the onshore transmission and distribution sector in which HIGHVOLT is an established market leader with over 250 systems already in operation globally. The new test system will be DNV certified and smaller in scale compared to the land based equivalent to allow for the demanding logistics of working offshore. Its modular design facilitates the testing of different lengths and types of cable.

As the offshore wind industry continues to expand at a high rate, it is critical for windfarm operators that post installation tests have the best chance of detecting any defects that could later lead to failures. According to the Offshore Renewable Energy Catapult (ORE Catapult) subsea power cable system failures (including cable accessories) are a frequent issue, causing approximately 75-80% of offshore wind insurance claims despite only making up around 9% of the total cost of a windfarm. The total cost to operators in 2019 was over £1 billion in lost revenue, and the figure is climbing year on year[1].

Of the cable system failures reported by the ORE Catapult, approximately half were caused by problems during the installation process[2]. This highlights the issue of traditional offshore test methods failing to detect defects arising during installation; resonant testing increases the probability of picking up such defects. IEC 63026 (published in 2020) stipulates a test frequency in the operating range of RTS for cables operating above 36 kV, precluding the use of existing technologies that have been used to date.

JDR is a market leader in the offshore inter-array cable market and is the first cable manufacturer to invest in this technology. As Ross Piercey states:

‘JDR has looked at what our clients need, to adhere to the latest IEC 63026 Submarine Power Cable standard and how we can support them to satisfy insurers the windfarm installation is fit for purpose. It’s clear that with the upgrade to 66 kV inter arrays, a more robust post installation test method is needed, to ensure the cable and all accessories are defect free upon install. We are delighted to work with HighVolt in bringing this, world leading concept, to our clients. JDR will be the first offshore test and terminations company to offer Resonance, VLF & DAC technologies to our customers.’

Ross Piercey- Asset manager, JDR Cables

HIGHVOLT developed this test system in response to the technical requirements and field experiences of key industry stakeholders. Given the potential reliability issues related to the increasing voltages in IACs it was clear that an improvement in test technology was required.

The system is due to be used on a major UK based offshore wind farm project mid-late 2021. For more information contact: HIGHVOLT enquiries: sales@highvolt.com, JDR enquiries: sales@jdrcables.com

[1] – ore.catapult.org.uk

[2] – wes.copernicus.org

About HIGHVOLT

HIGHVOLT is the leading global supplier of high-voltage and high-current testing systems and measuring instruments with more than 115 years of experience and an export share of around 90 percent. At its Dresden site (Germany), HIGHVOLT develops and produces systems for testing electrical power equipment for the transmission of electrical energy such as transformers, cables and switchgear. The company offers complete solutions with all consulting and maintenance services from complete test fields, test systems to specialised components. HIGHVOLT is a member of the Reinhausen Group.

About JDR Cable Systems

JDR’s world-leading solutions bring power and control to energy systems in the global offshore oil, gas and renewable industries. For more than 25 years, we have built our success on our technical expertise and reliability. Every market we enter, every customer we serve, and every project we deliver benefits from exactly the same dedication to technical quality, service and support.

In designing, manufacturing, delivering, installing, and supporting subsea power cables and umbilical systems, our engineers and manufacturers are committed to providing products and services of the highest quality. We deliver consistently reliable solutions through our specialist engineering and experienced project management teams. Our 24/7 service and support throughout the product lifecycle meets even the most complex and demanding project requirements.

About TFKable Group

TFKable Group is a leading global producer of wires and cables, with major production facilities in Europe and sales offices globally. With its HQ in Poland, TFKable Group consists of several trading companies, with a significant number of production plants around Europe and a Cable Waste Recycling Department in Poland. TFKable Group offers 25,000 types of wires and cables, which are sold in 80 countries. With a consistent growth strategy based on client portfolio diversification, TFKable Group has cemented its position as a world leader in the cable business, with significant further development potential.